[Leland] The packages finally arrived and David was able to put the belts on the Port engine. After our unexpected week in Charlevoix, we were ready to get moving – albeit with the loose prop on the other engine still. At this point we were starting to get nervous about the approaching end of the season – we really don’t want to be stuck on Lake Michigan when everything freezes for the winter. With us finally being back on the move, we started calling places again to figure out where we could get hauled out. Since we are quite heavy and wide, the number of places with a travel lift large enough to safely haul is is quite limited. Add that to the fact that most places on Lake Michigan at this time of year are fully booked with hauling out boats for permanent winter storage, we were beginning to panic! We luckily managed to find a shop in Grand Haven that agreed to haul us out. This just meant that we needed to get 100 miles south on the one engine!

We made it to Leland the next day, which is famous for its “Fishtown” a still-working historic fishing village. This turned out to be one street/dock, which was unfortunately closed while we were there! We had a great meal at a restaurant right by the marina for our first night. The next day strong winds were expected, so we stayed for another night. Since we worked and I made dinner on the boat, we didn’t do any further exploring.

The next day, we headed towards Luddington and tied up on the wall at their marina. Our friends from Mackinac Island caught up with us and our schedules finally coordinated for us to eat dinner together. After dinner we went on a mission for ice-cream and ended up at a popular local spot with a huge line!

We headed out early the next morning for the remainder of the cruise to Grand Haven. Since we’d told them that we would be limping on one engine, they had not expected us until the evening. However, we had figured out that the engine vibration was worse in the mid-range of speed, but we could go on plane just fine. David assured me that it was extremely unlikely that we would entirely lose the prop, and since we didn’t fancy a looooooong day going 4 knots on one engine, we decided to plane. We arrived in the middle of the day when they were non-stop lifting out boats with their forklifts. They told us to return after hours, so we headed a little further around in the corner and dropped anchor. Since it was a lovely day, we decided to go for a quick swim, which might be our last until we get back to Florida! It was a lovely afternoon.

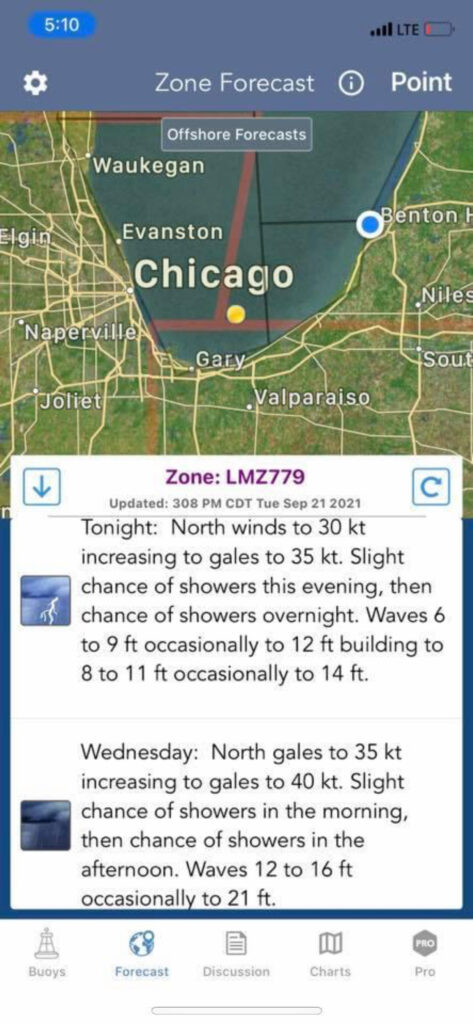

Early the next morning, we were hauled out. Within minutes someone was taking a look at the loose propeller and had it fixed in about 15 minutes. David had checked the weather report and we were looking at several upcoming days of strong winds. Notice the predicted wave height on Wednesday…21ft!!!!!!

We decided to have the shop take a look at a few other issues (leaking through hulls etc). At this point, we’re pretty old-hat at living aboard while on the hard. And at least here the showers are fresh water!!

It was a fairly low-key week here. Unfortunately David wasn’t feeling too well (not Covid! common cold). There was a great running path right by the marina. As usual, the work took a little longer than expected and we ended up still there over the weekend. One of David’s college friends also happened to be in the area on vacation, so we scootered into town to meet up for the afternoon. There was a Latinx festival going on in town, so we ate some delicious street food.

On our last day, I ran into town for an errand and decided to stop at one of the wineries in town for a wine tasting. Again, the weather was warm, so I sat outside and enjoyed some wine while reading my book.

When we were finally put back in the water, it was in the afternoon, so we travelled about 2 miles down the river to the main Grand Haven town marina for one night. Unfortunately, this was far enough for us to discover that fixing the loose prop had not solved our engine problems. After some filter changing and a conversation with a Yanmar tech, we determined that the problem is likely the injection pump assembly. Unfortunately this is an extremely expensive part to replace, Yanmar-approved rebuild shops in the US seem non-existent (there’s one in Europe!), and Yanmar technicians are few and far between, booked up for weeks, and not amenable to flying out to meet us. So we are in a bit of a quagmire at the moment, but our top priority is getting to Chicago and into the inland rivers before Winter Comes!

Guess you’ll have to come up Europe 🙂

Thanks for the great blog- we enjoy reading about your adventures. Hope to see you at MBYC one of these days

Someday! :). We miss you all.